Challenge to world-class manufacturing

that only we can do-Aiming to be the No. 1 in the global niche-industry

The methods we developed are original. The origin is from Germany, however we succeeded to develop idea into revolutionary method using manufacturing technologies. We are pursuing things that only NT Engineering can do with our technological capabilities that are second to none in the world and our passion for manufacturing that makes the impossible possible.

Looking to future needs, we are aiming to become technology that goes beyond common sense, aiming to be a global niche top company that maximizes the fine boring technology cultivated through the technical partnership of a Japanese-German joint. Since 2015, we have started a new stage of our business. Independent of the joint venture with Germany. In Aichi Prefecture, which can be said to be the center of Japan's manufacturing, we contribute to a wide range of industries, including the major automobile industry, with innovative and original NTE brand products with high precision manufacturing, sales and processing technology.

NT Engineering will continue to work on total products from the correction tool to measurement & monitoring device and will strive to create a new idea from a unique perspective toward automation or unmanned operation.

Revolutionary "Tool correction system"

It can be said that even higher quality is required for processing accuracy on a special-purpose machine and general-purpose machine production line. Automatic tool correction setting cannot be performed with the only diameter adjustment function .

Therefore, in order to break the conventional knowledge that "correction up to the micron range is impossible", our correction holder is combined the "actuator technology" that utilizes an elastically deformable structure with the "control technology" . We continue to lead the industry by providing a highly accurate correction system in the micron range by original technology.

"Measurement system" that enables the impossible

Meet customers' needs for high precision and high quality at manufacturing sites.

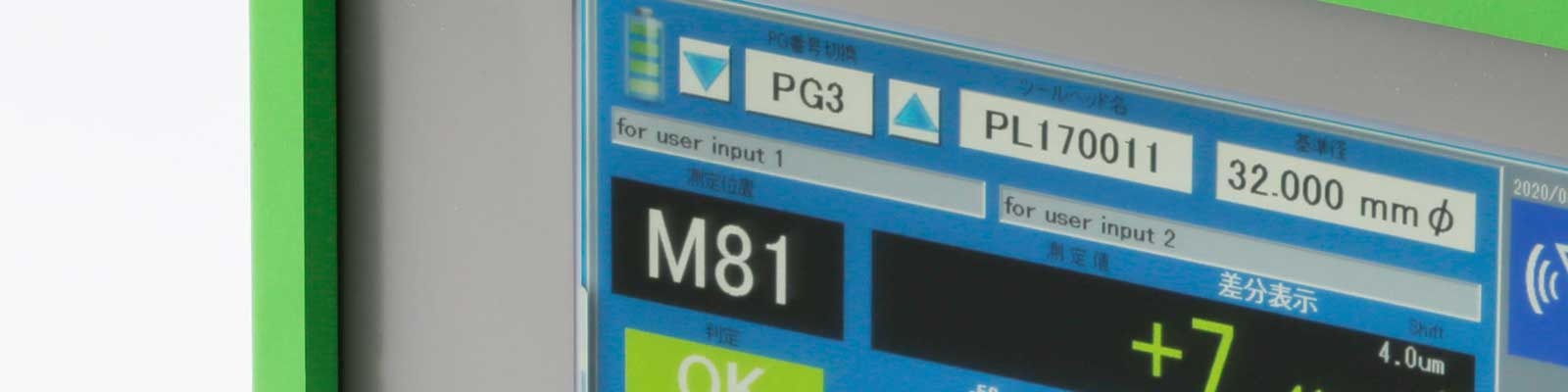

No matter what kind of high-precision machine tool, wear error of the cutting edge in the micron unit is unavoidable in machining.

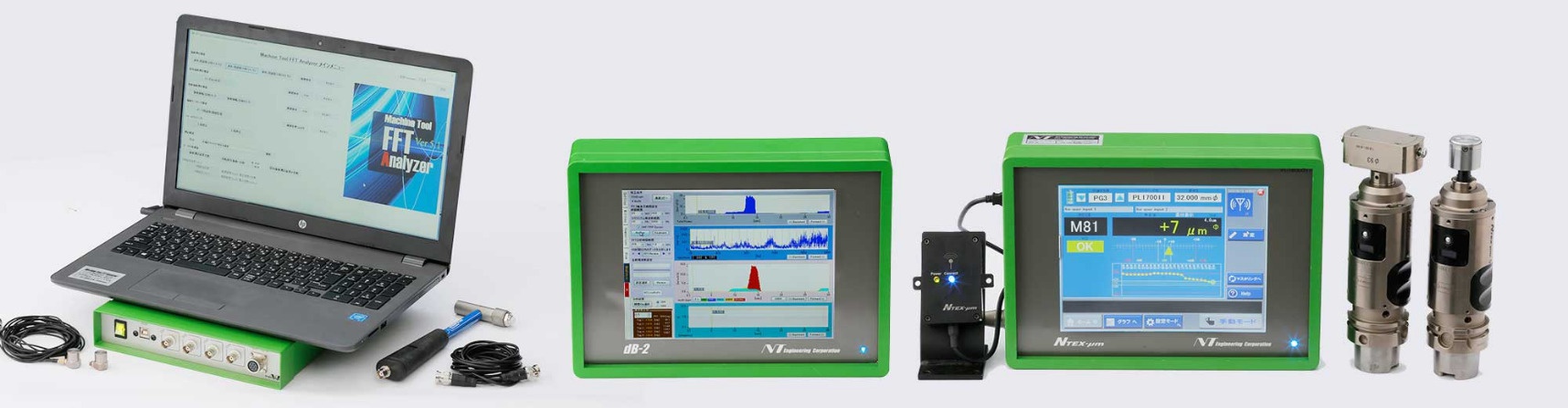

We have sell measuring system that feeds back to the processing machine.

For maintain machining accuracy and quality, our products measure the micron error that occurs in the boring processing parts, judge the measurement data , and feed back signal.

"Vibration measurement / vibration monitoring device"

that contributes to higher precision and productivity

Improve production efficiency by visualizing problems.

We have developed and manufactured "Machine Tool FFT Analyzer" with the concept that anyone can easily handle it, as an improvement tool for solving difficult processing problems such as chattering, further improving cutting quality and improving productivity.

The best way to maintain machining accuracy and improve the rate of operation machine is to look at vibrations which contain a lot of machining information.

We believe that it is indispensable to develop a technology to monitor this for constantly monitoring the machining state in real time to detect the sign of abnormality.

We are promoting the commercialization of more user-friendly products through software technology and wireless communication technology. At the same time, we are working to develop cutting-edge mechatronics products with the goal of processing monitoring equipment aimed at labor saving and unmanned operation, and AI with "concept beyond common sense".

Business

Fusion of advanced technologies and global expansion of NTE brand

"Samson AG", "Samsomatic GMBH " in Germany and "NT Tool Corp" in Japan established a partnership and created "NT Engineering ." in 1979. Innovative and original NTEX-SC brand products created by the fusion of Japan's advanced manufacturing technology and Germany's elaborate basic theory are widely valued by customers in the automobile industry, home appliance industry, who have global operations in Europe, America, Asia etc.

As a base for overseas business expansion in order to respond to such patronage, in 2002 we concluded an agent contract with "EMDEETEC (Bangalore)" in India, and in 2004 we established an office in Dalian, China and worked to expand sales channels.

In 2015, the joint venture with Germany was dissolved and we are independent. However, mechatronics technology and IoT (Factory-automation) technology with German universities and research institutes, the connection is unbroing in the future too.

While high processing accuracy and quality are required in the future, we will not only promote the development that is globally applicable, but also look after to follow up with the local customers and back them up with products that go beyond the field of tool correction system. As an edge tool for production equipment, we will provide the products aimed at labor saving and unmanned operation.