Easy micron correction

Significant reduction in setting time and automatic correction support

Product features

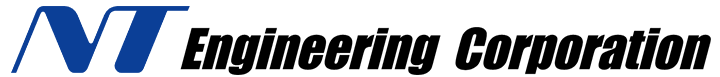

Automatic correction with pushing unit attached to the machine

- Easily attaches to a standard machining center and anyone can easily adjust the diameter in micron units either manually or automatically. (Reduction of adjustment time)

- To adjust the diameter, just push the push button with a light force.

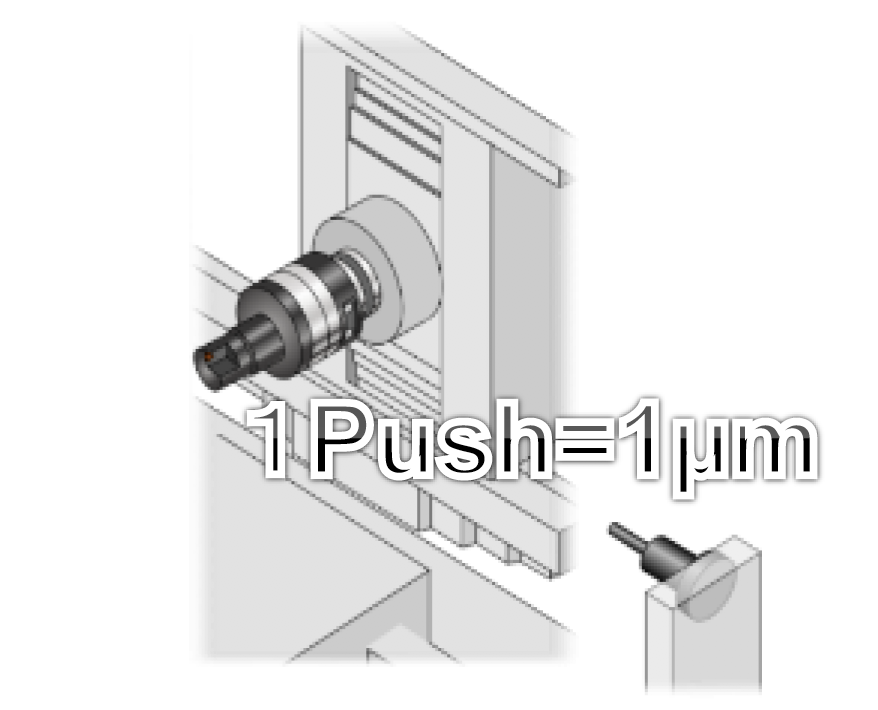

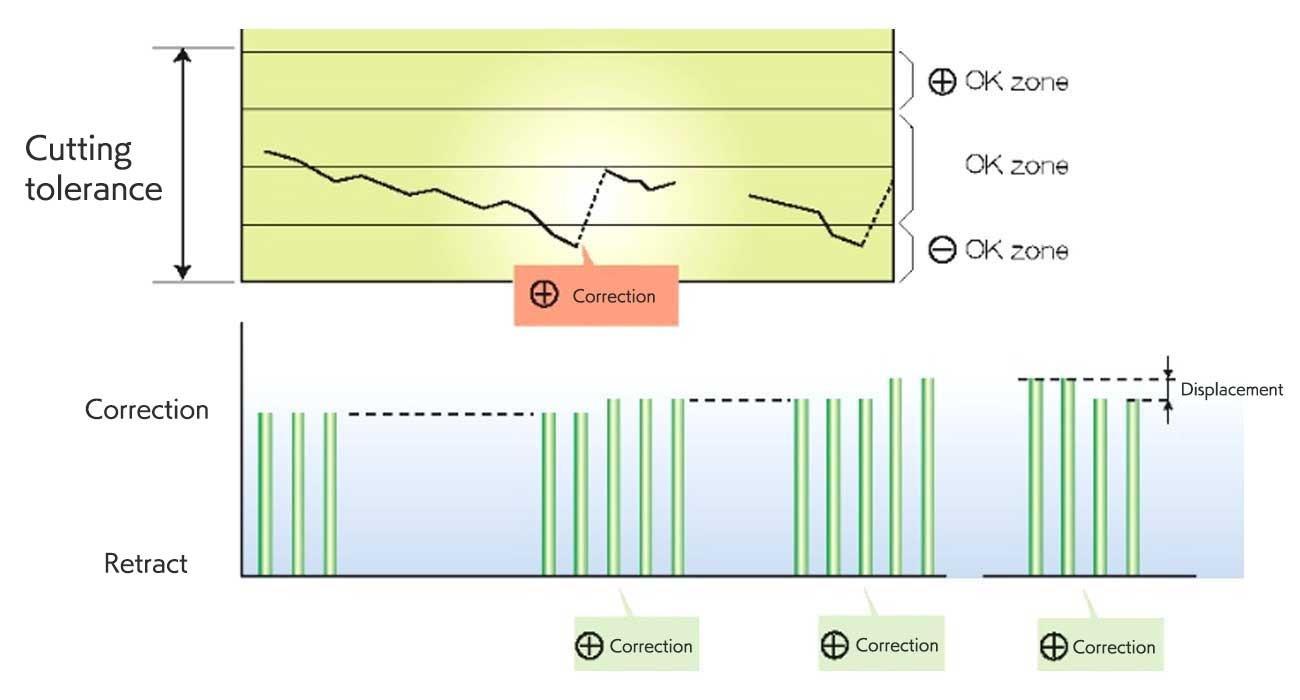

- Automatic feedback correction for machining is possible in combination with measuring equipment. Productivity can be improved by maintaining stable processing quality.

- Compatible with BT30 equivalent shanks. Realization of automation/labor saving even on small machines

(Simple & compact: BT30/HSK50A shank specifications available)

- There is no need to install a dedicated controller, and the axis movement of the machining center can be used to easily adjust the diameter in micron units by the number of push-button presses.

- The correction amount is proportional to the number of pushes. No need for troublesome work such as applying a dial gauge to the cutting edge to make fine adjustments.

- Correction amount

- 1.0±0.5 μm/1 push (2±1 μmφ/1 push)

- Corrected working amount

- 150 μm (0.3 mmφ)

For BT30: 100 μm (0.2 mmφ) - Push button pushing force

- 80N

- Weight

- 1.7 kg (excluding shank and boring bar)

- Rotation speed

- up to 4,000 rpm Balance class G2.5 class

- Shank size

- BT30/BT40/HSK63A/BT50/HSK100A

(The shank part is separated from the main body) - Note

- center-through coolant can be supplied (Max. 2MPa)