Quantitative correction just by pushing the push button.

High quality machining is maintained by automatic feedback compensation.

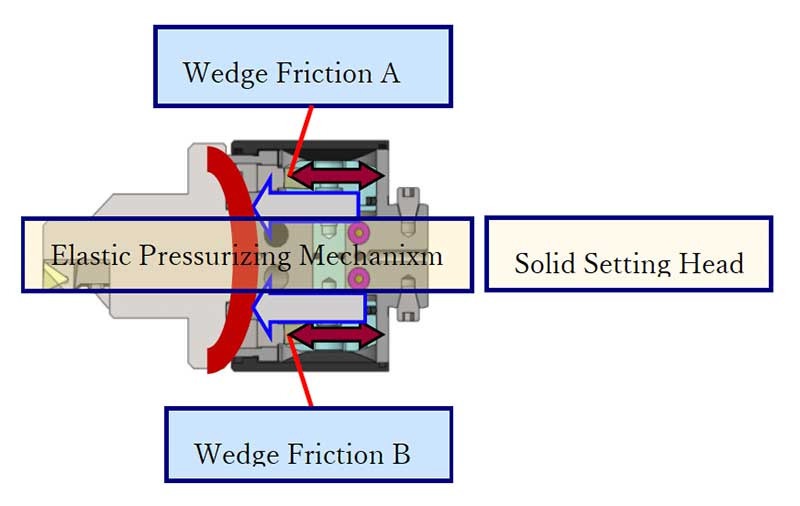

Product features

- 1 push / 1 micron correction by push button

- Compensation operation is completed with a light pushing force (about 40N).

- Compact housing

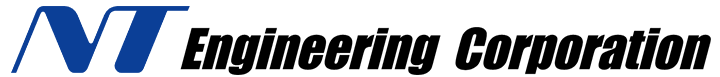

- The original pressure boosting mechanism converts the power to about 100 times, and the tilting wedges facing each other forcibly correct it.

Tilt compensation developed by technical know-how for elastic deformation. - One push "1 micron (φ2μm)" and quantitative correction

- No dial gauge is needed to see the amount of movement. The troublesome work of locking after performing the correction operation is not necessary, and the correction operation can be done quickly with Easy, and the machine stop time can be minimized.

- Correction can be changed not only manually but automatically

- Manpower saving/unmanned support possible

Zeta-1 ATC correction head specifications

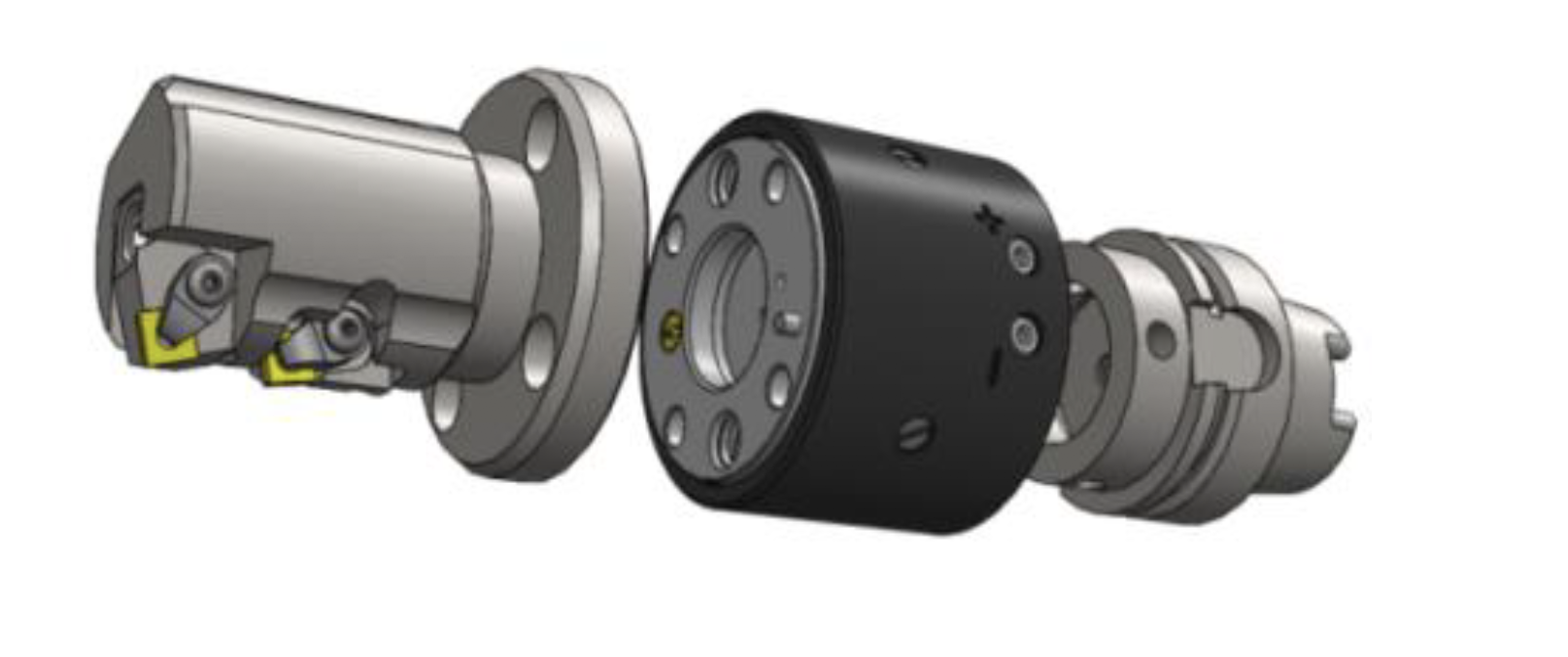

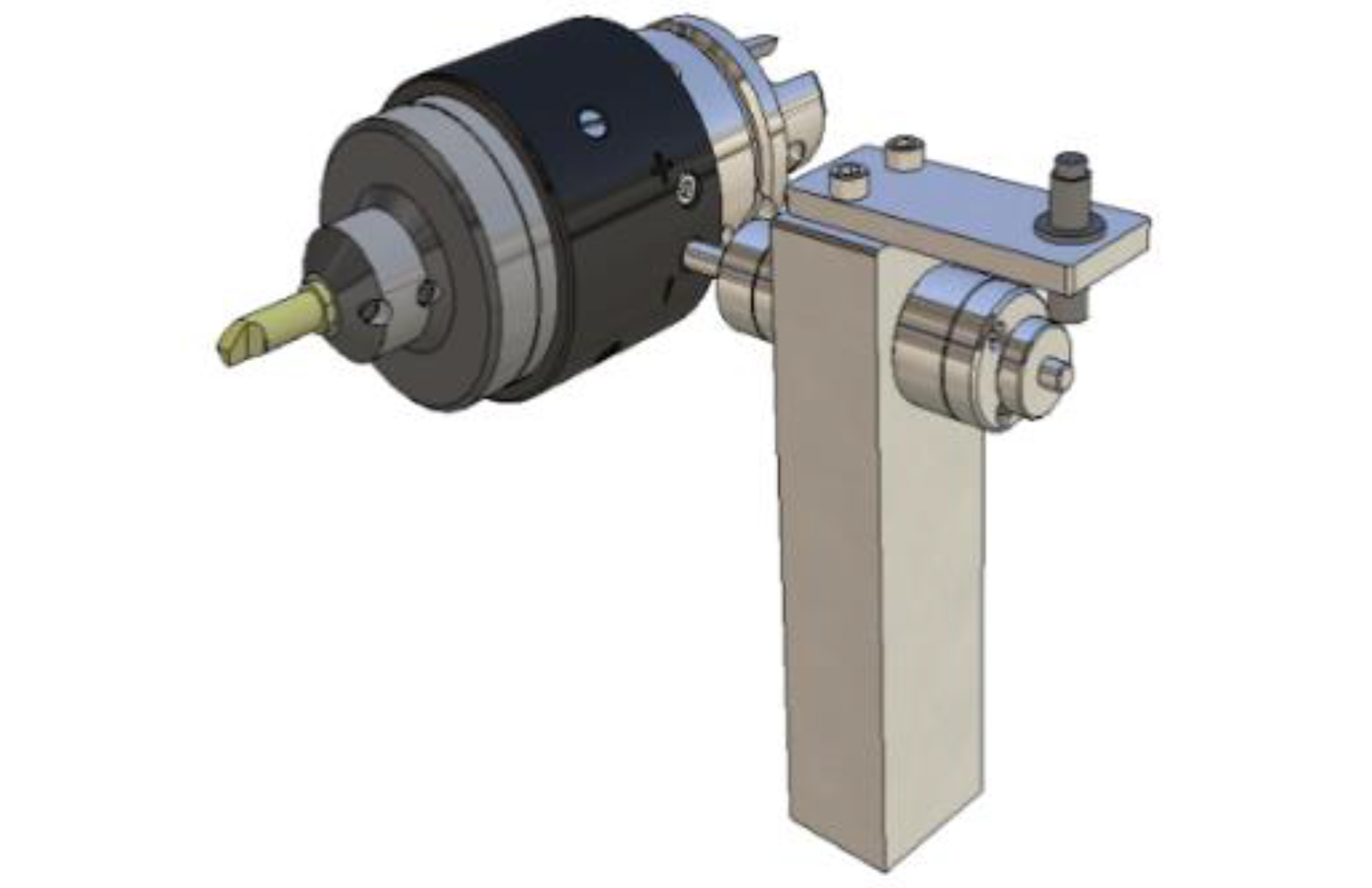

Illustration of pushing unit on machine

- Correction amount

- 200 μm (0.4 mmφ) ±100 μm/r from center axis

At the position 100 L from the frontend face of the correction head - Correction step amount

- 1μm(r)±0.5μm / push

- Shank shape

- ① BT40 (See the figure below)

② BT50 (optional)

③ HSK63 shank (see the figure below)

④ UTS6350 shank (option, see the figure below) - Weight

- ≒3kg (For BT40/HSK63/HS63) Does not include boring bar

* Through spindle coolant is also available as standard specifications.

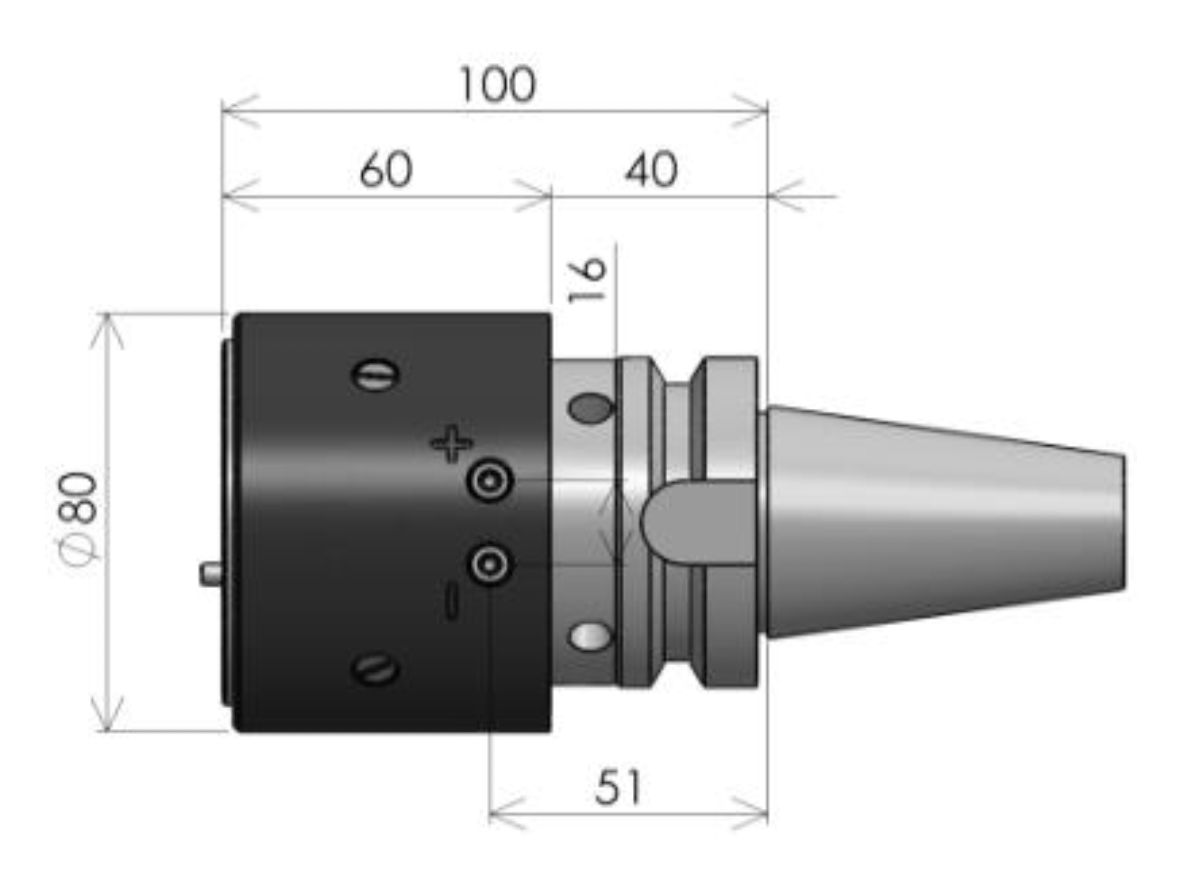

BT40 specification (Reference)

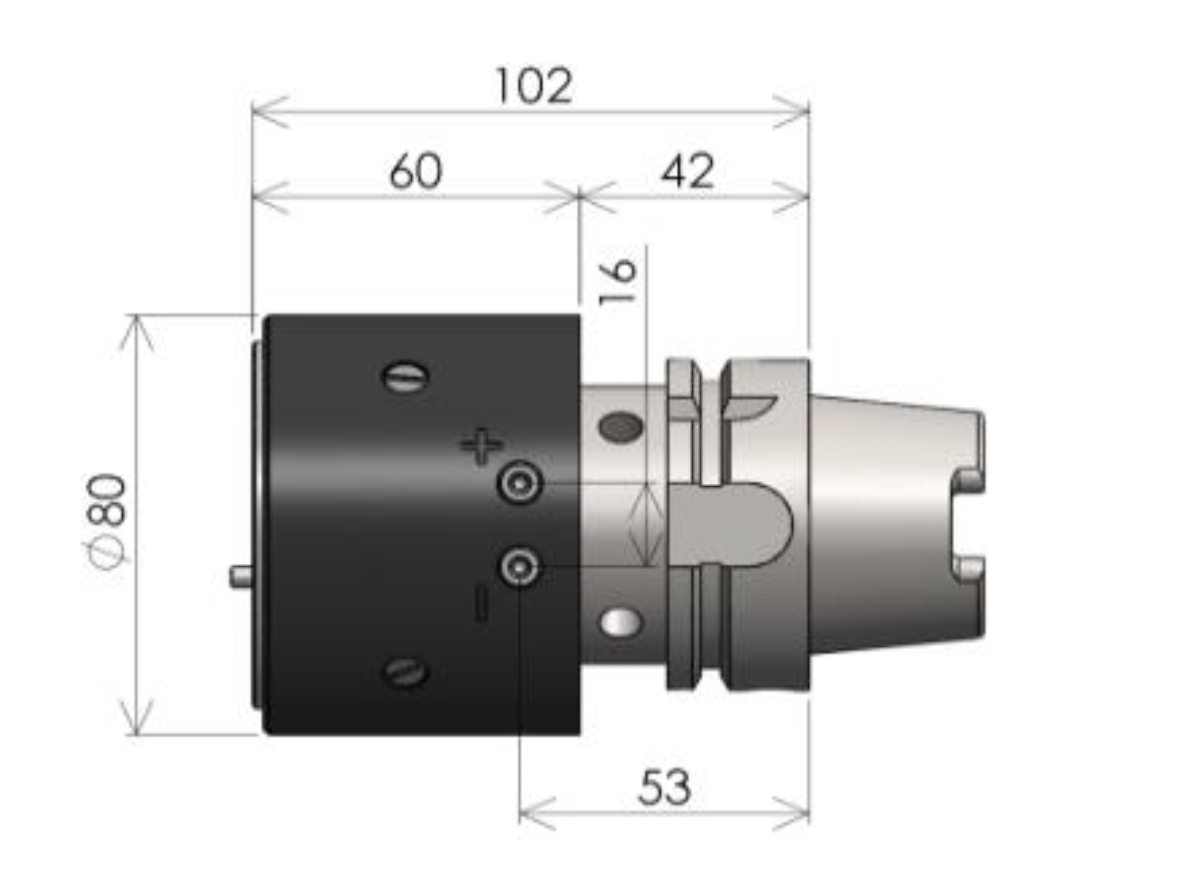

HSK63 specifications

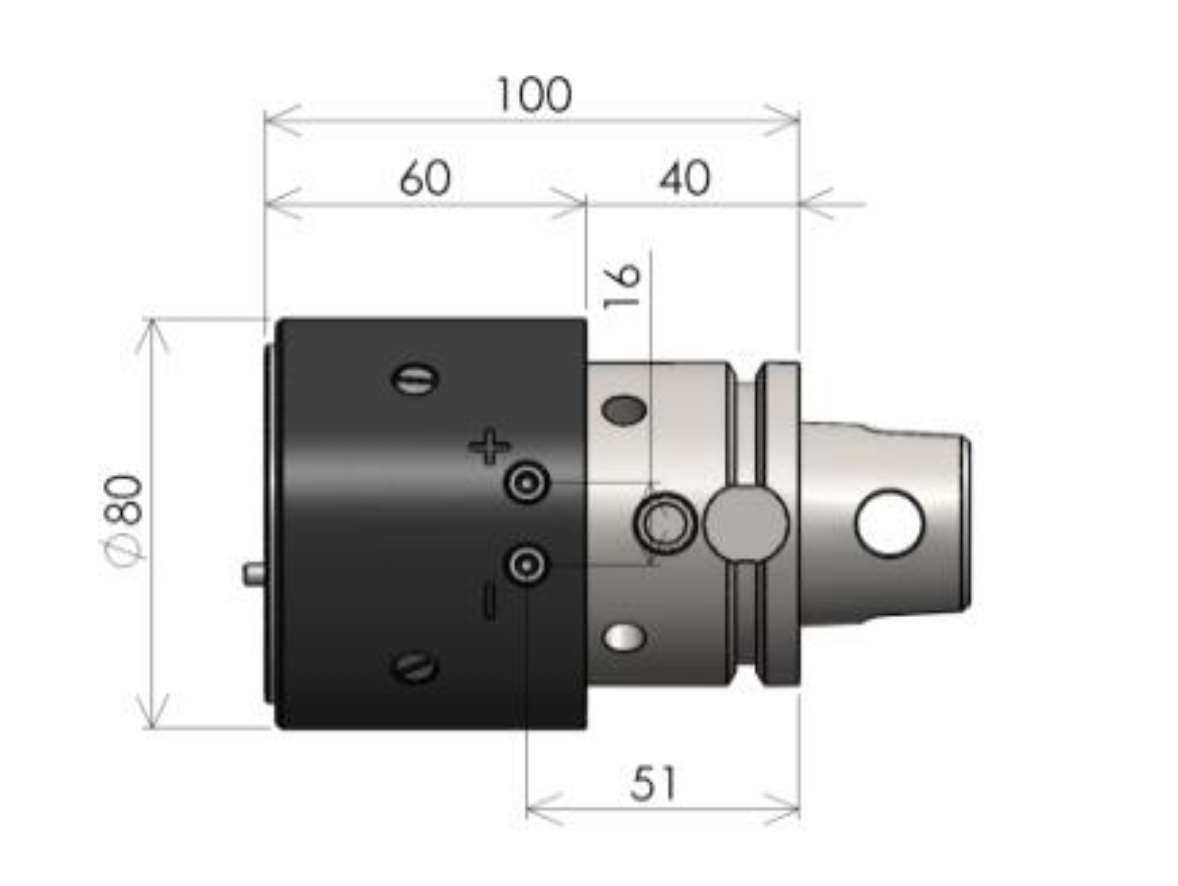

UTS6350 specifications

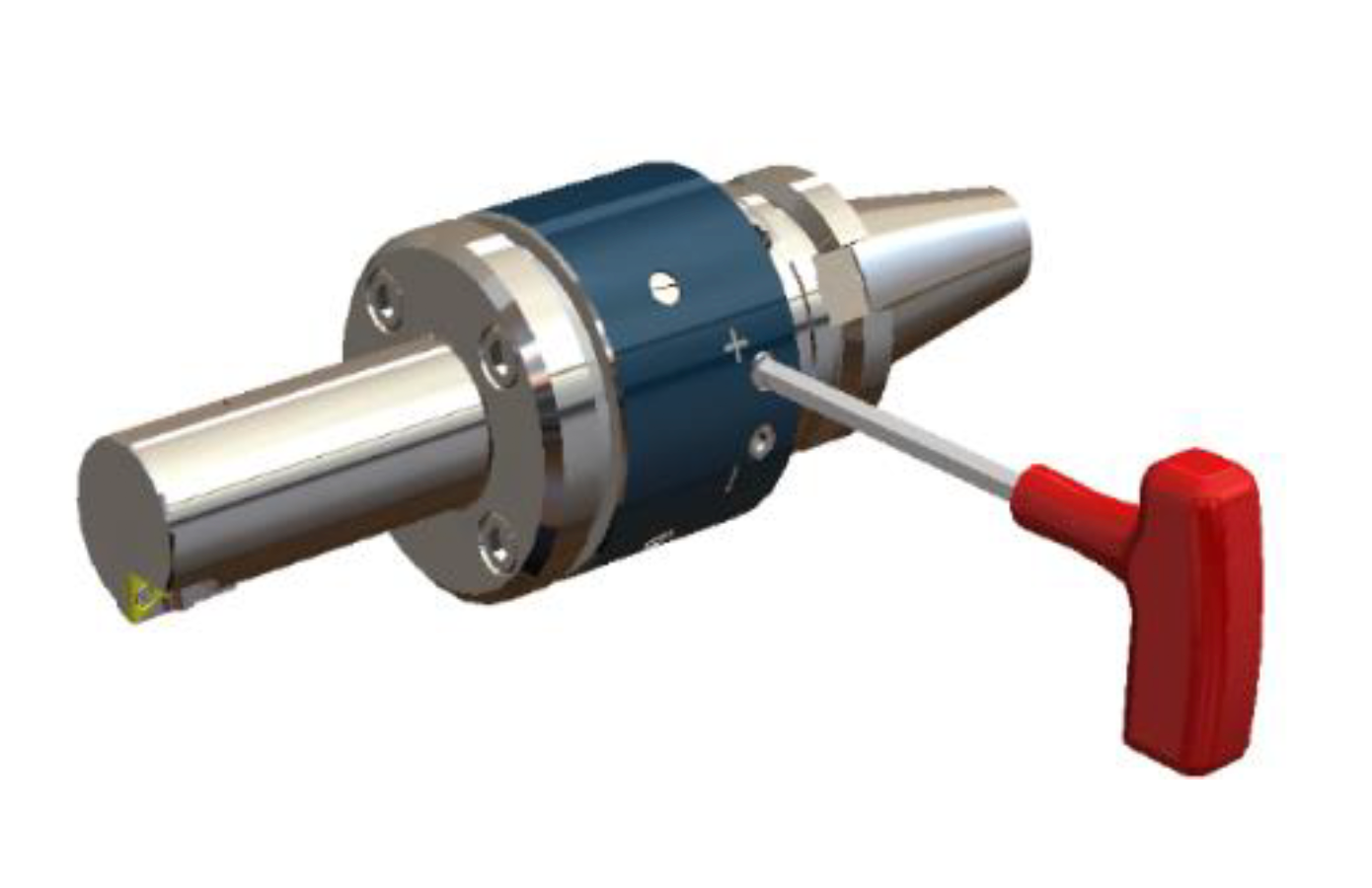

Manual correction

Automatic correction

Even when performing presets on/off the machine or when making automatic corrections, you only have to use the push stick to press the plus and minus push buttons as many times as necessary.

The operation is easy and quick, and the tip edge adjustment time can be shortened.