Micron correction by push button.

Reliable correction operation with a light pressing force.

Product features

- Zeta-2 is an ATC type correction head that has high rigidity and damping characteristics for use in finishing deep cylindrical holes such as cylinder boring.

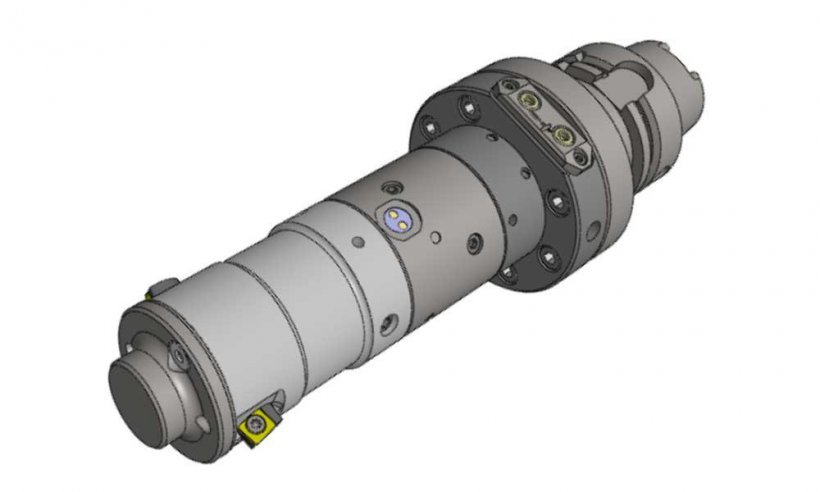

- By pressing the push button on the main unit, the plus/minus correction operation is performed, and the push force of the push button is as light as about 3 to 4 kg. The pushing force is increased by a unique hydraulic mechanism inside the correction head, and the tapered cone type sliding body of the wedge mechanism moves in the axial direction by this operating force, and the oval elastic body expands and corrects.

- A unique compensation structure that attaches cutting edges to the two vertices of the housing that deforms into an oval shape and moves them together. The movement of the cutting edge is a method in which the two edges move facing each other by the same amount, and there is no loss of balance.

- The correction can be changed not only manually but automatically.

- Manpower saving/unmanned support possible

Zeta-2 ATC correction head specifications

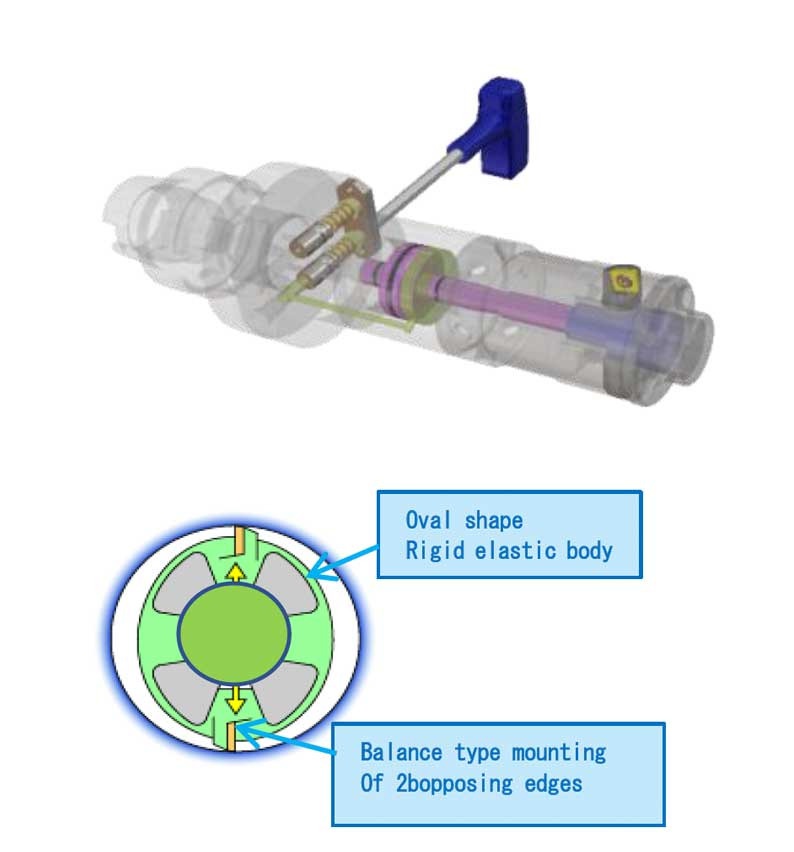

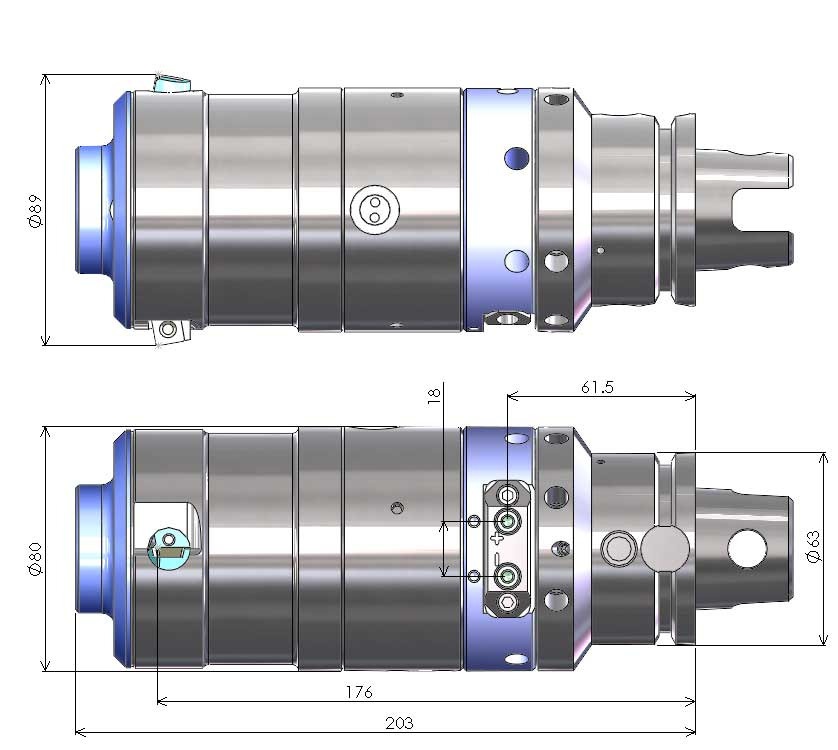

φ78-BT40 Reference Diagram

φ89-UTS6350 Reference Diagram

- Correction amount

- 150μm(0.3mmφ)

- Correction step amount

- 1μm±0.5μm /Push

- Compensation push button pressure

- 40N

- Weight

- 約8Kg [75φ Processed goods]

- Maximum working speed

- 7000RPM

- Shank shape

- BT50/BT40 shank equivalent HSK shank and UTS shank

*Through spindle coolant available

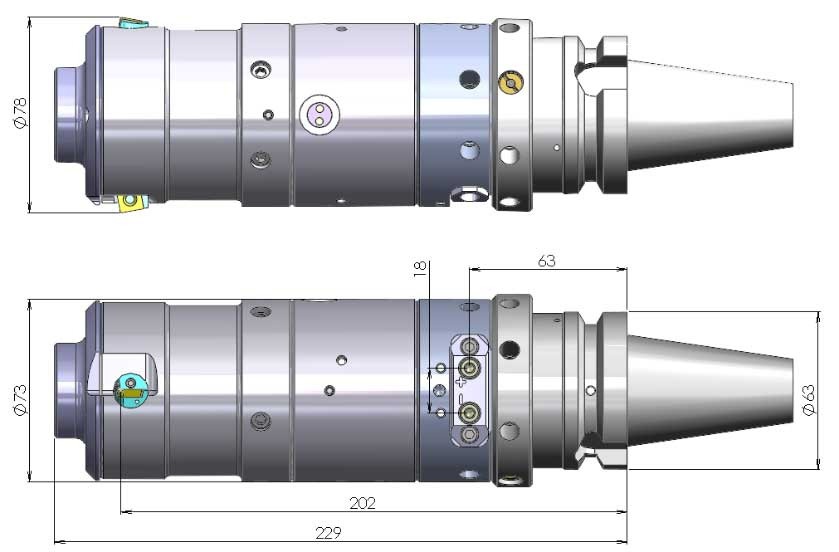

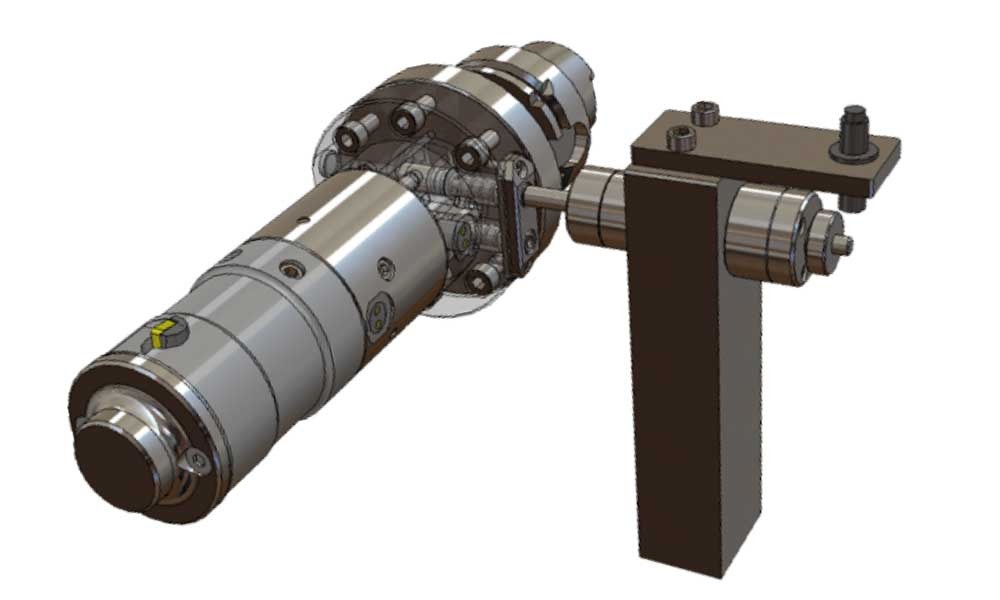

Automatic correction with pusher unit attached to the machine

Even when performing presets or automatic corrections outside or inside the machine, the correction instruction simply pushes the plus/minus push button as many times as necessary with the push rod.