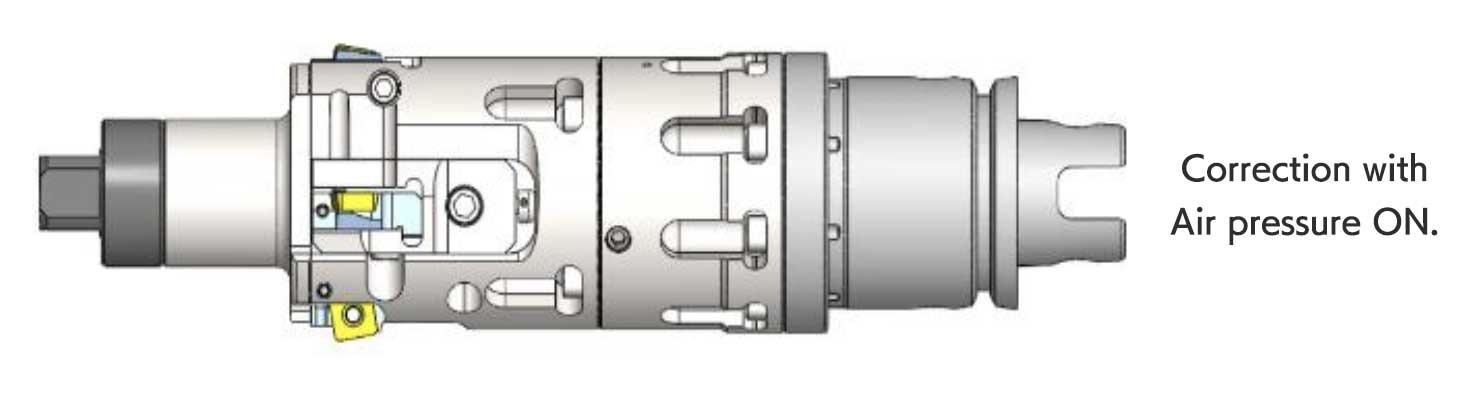

Utilizes the S-axis function of the machine

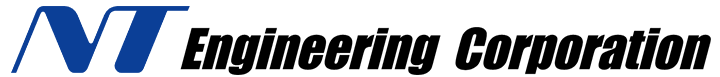

Multi-edged ATC correction holder with retract function

Product features

Utilizes S-axis function of NC machine

To change the amount of operation, control the position of the stopper at the edge, and to operate it, drive the center shaft with air pressure (or coolant pressure).

* There is also a specification of a direct acting S-axis holder that does not use the pressure of the working medium and does not have a retract function.

Pressing with a fixed medium finishing edge / reciprocating with pulling by expanding the finishing edge at the forward end

The ATC time is shortened by integrating the intermediate finishing holder and finishing holder.

The original mechanical structure head is a 2-edges facing processing that suppresses oscillating vibration with a high rigidity and high damping design.

- As an example of arranging 4 edges, 2 fixed edges are arranged on the fixed solid main body and 2 finishing edges are arranged on the deformable body, each 2 edges facing each other, and the finishing edges facing each other has the same amount of correction operation is performed. Design that does not lose balance in all operating areas.

- It is possible to reduce the cutting torque applied by the balance cutting with 2 edges and perform the processing with oscillation vibration suppressed. Stable shape accuracy can be obtained by the same amount correction with 2 edges at the same time.

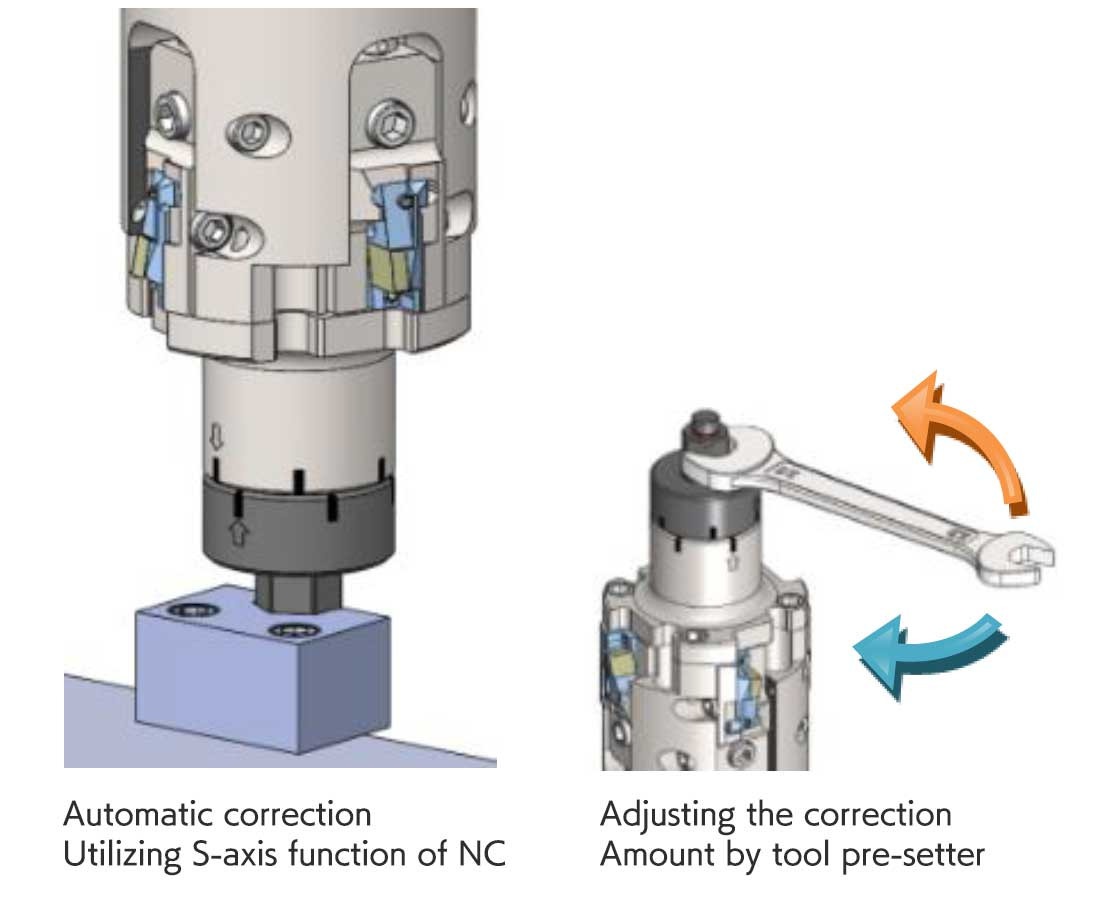

- Setting Length

- 100μm(0.2mmφ)by 4 edge Spec. 200μm(0.4㎜φ)by 2 edge Spec.

- Setting step amount

- 1μm±0.5μm/60°rotation(or 90°rotation)

- Weight

- Approx. 8kg(80φ Processed goods)

- Rotation speed

- Max. 6,000rpm

- Shank size(Spec.)

- BT50 , BT40

HSK100A, HSK63A

UTS10080. UTS6350