Simple Air-Micro measuring for Environmentally Friendly

Product features

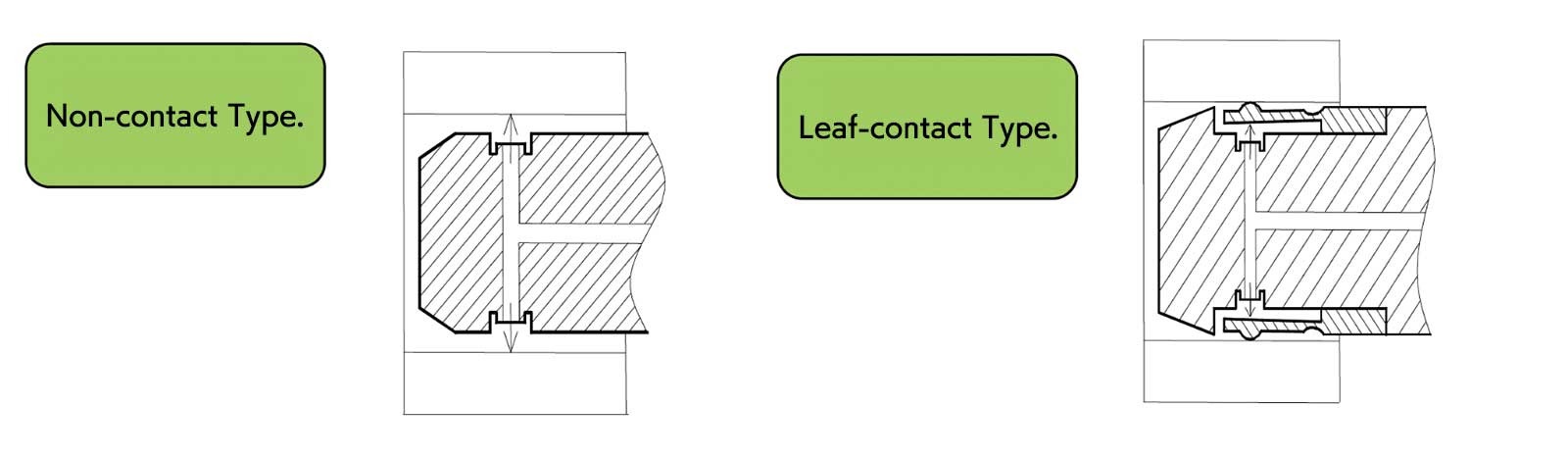

Air direct blowing non-contact measurement

- Does not damage the work piece.

- Can be used in adverse environments where coolant is used

- Simple structure (less failure)

- In machine or outside machine measurement are both possible.

Leaf contact type

- Measure the same as the cylinder gauge

- No effect on surface roughness

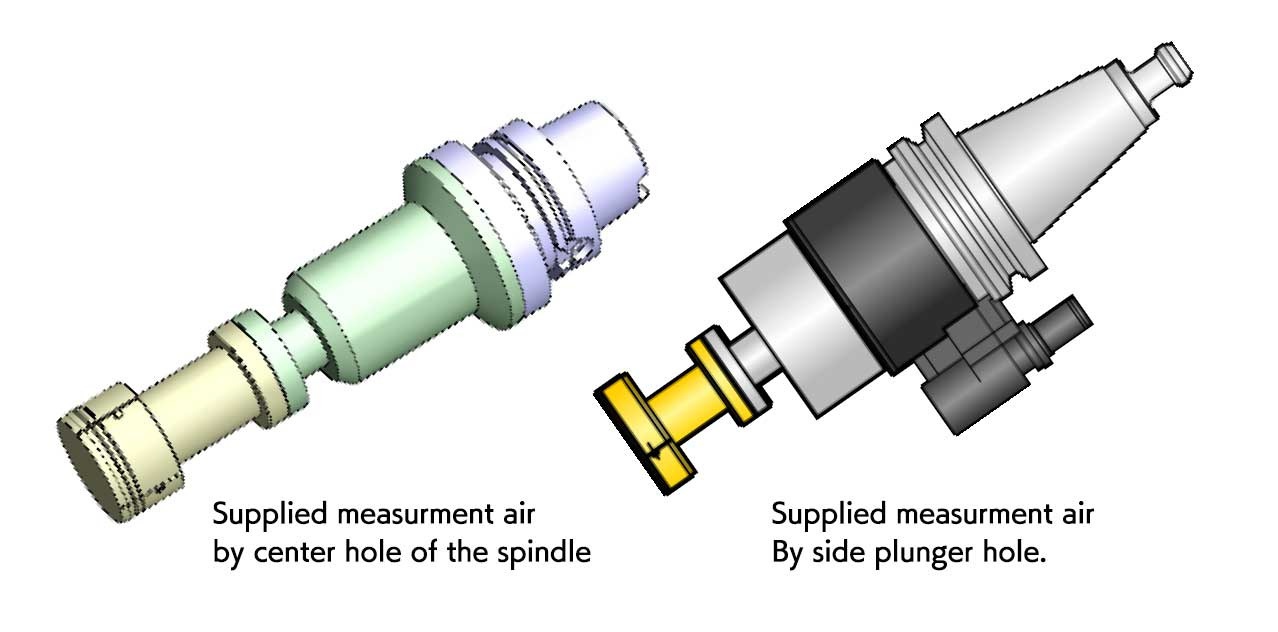

Air direct blowing non-contact measurement

- Non-contact type air micro head with a nozzle built into the ATC holder is also available. (For general-purpose machines)

- Measurement air is transmitted to the measuring head from the center hole of the spindle or the side plunger hole. The back pressure is detected for comparative measurement with mastering.

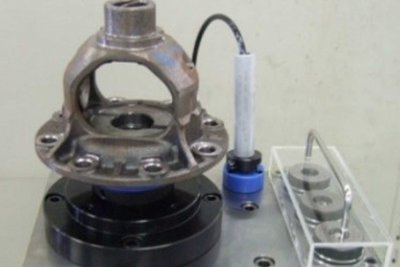

Semi-automatic measurement reduces both the burden on workers and contributes quality control.

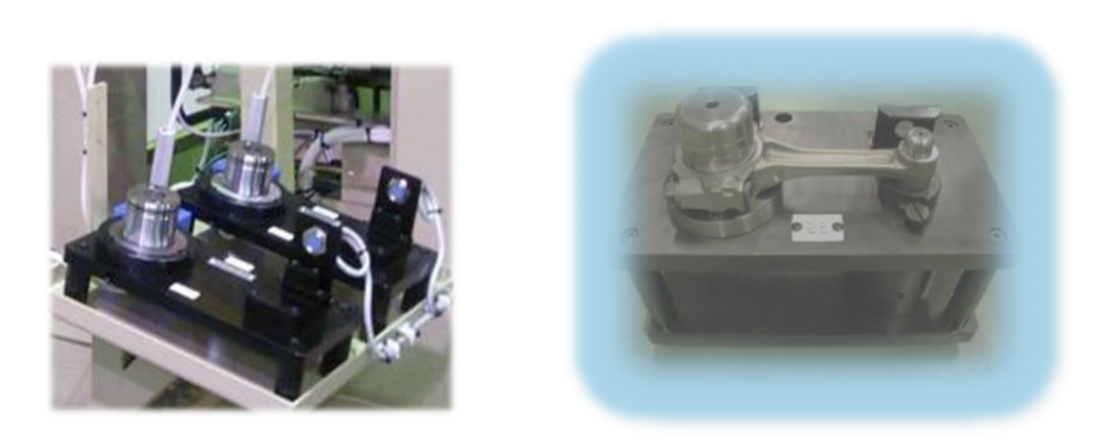

After machining the connecting rod large and small end holes, the operator manually attaches to the measuring table. This is an example of semi-automatic measurement inserted in the measuring head.

A workpiece can be removed from the machine with a robot by placing an arc on the measuring table outside the machine, the presence or absence of the work is detected and the measuring head moves up and down.

For problems such as being unable to increase the cost of measuring with a fully automatic measuring instrument, or not being able to secure a large measurement space, we will ask about the problems and troubles, and then select a measuring method that matches your needs.

We will propose and help your improvement.

By using a semi-automatic measurement method, work time can be shortened and the burden on workers can be reduced.

In terms of quality control as well, measurement data can be saved for later review.