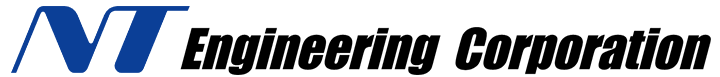

A highly practical device that anyone can use easily and immediately.

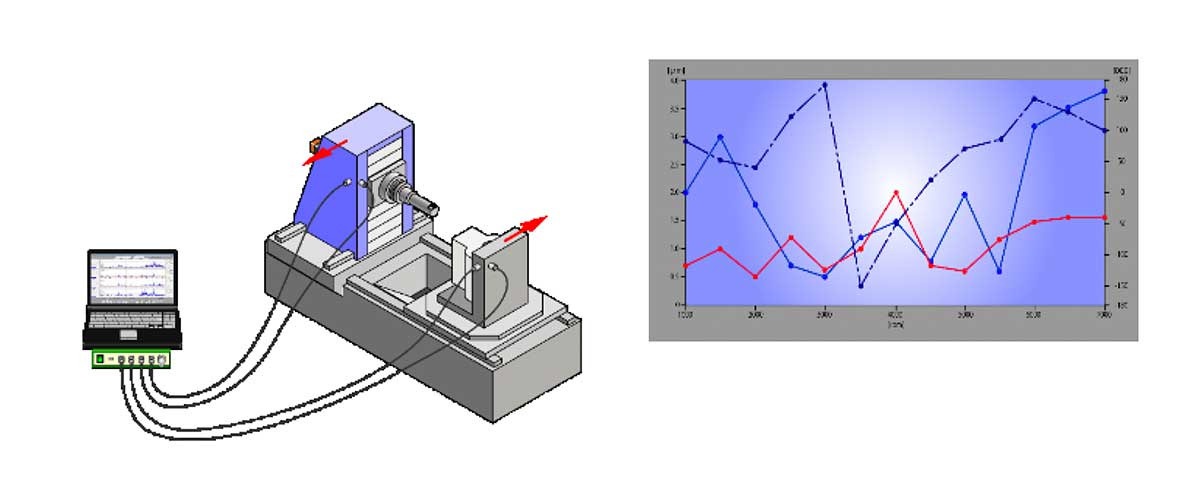

Improved processing by "visualization" of vibration.

Product features

When imperfect circle boring or chatter occurs , the effect of using the result in analysis and cause investigation is enormous. Visualizing vibration by FFT analyzer. Equipped with user-friendly operation along the guidance display and practical functions that is necessary for vibration measurement and analysis of machining. Using the stable pocket method, the recommended rotation speed display for avoiding regenerative chatter is drawn.

① Machining vibration measurement function

The acceleration sensor is used to display the acquired vibration as a vibration waveform on the time axis and a spectrum on the frequency axis. (Up to 10000Hz range)

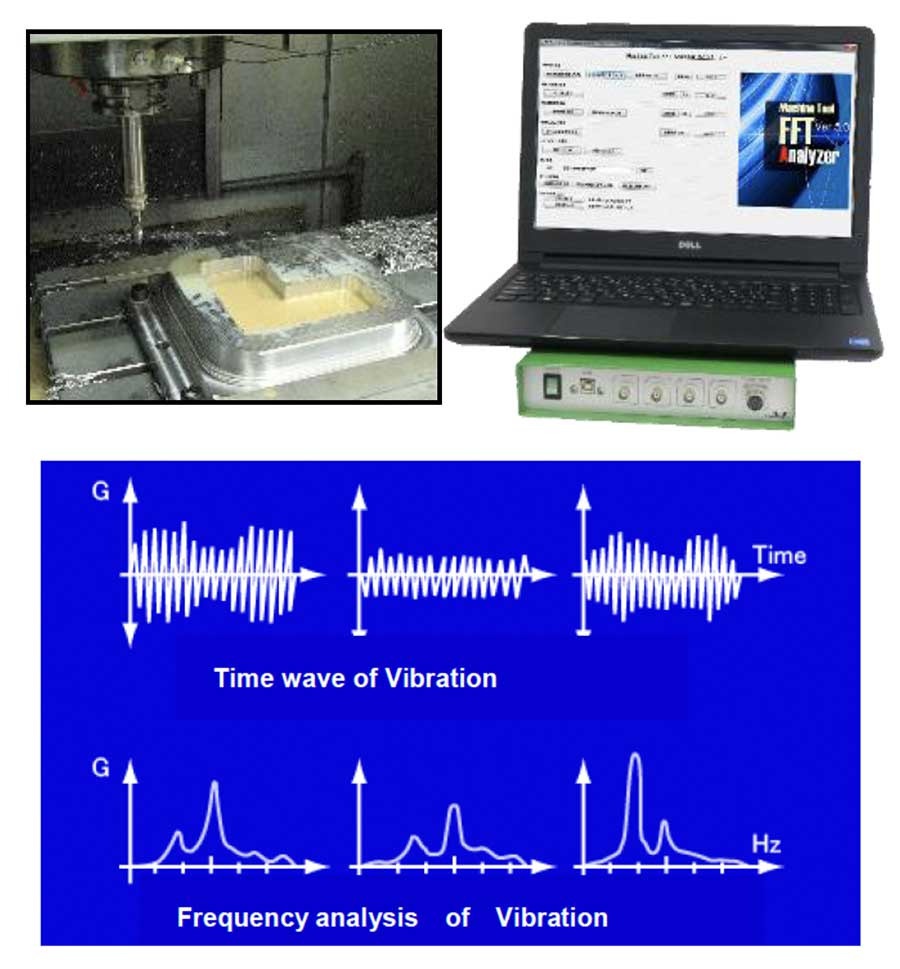

There are 1Ch screen, 2CH screen, and 4CH screen.

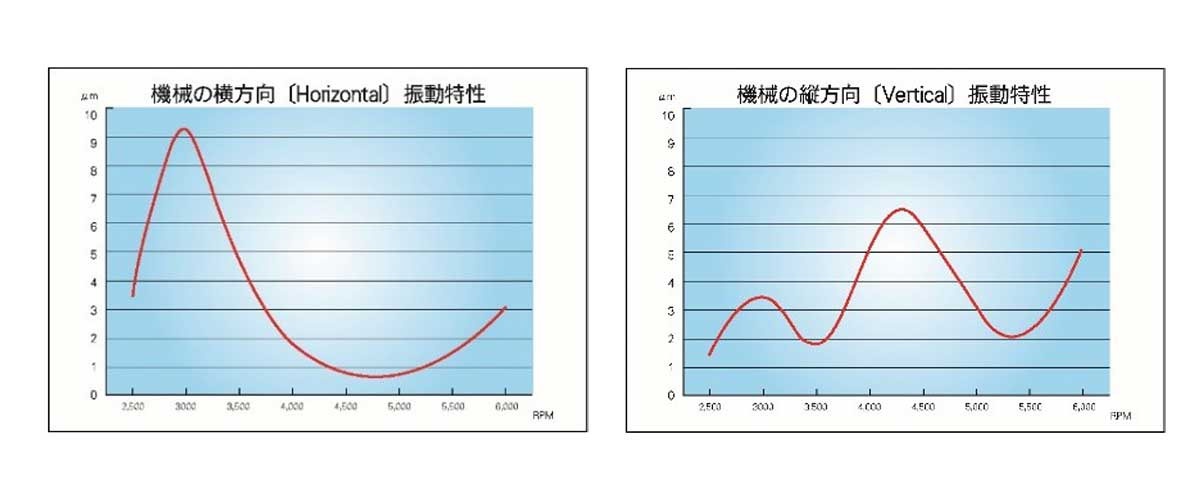

② Natural frequency measurement function

It is very important to know the natural frequency when improving machining accuracy and dealing with chatter. The stable pocket area is estimated from this data and processing parameters.

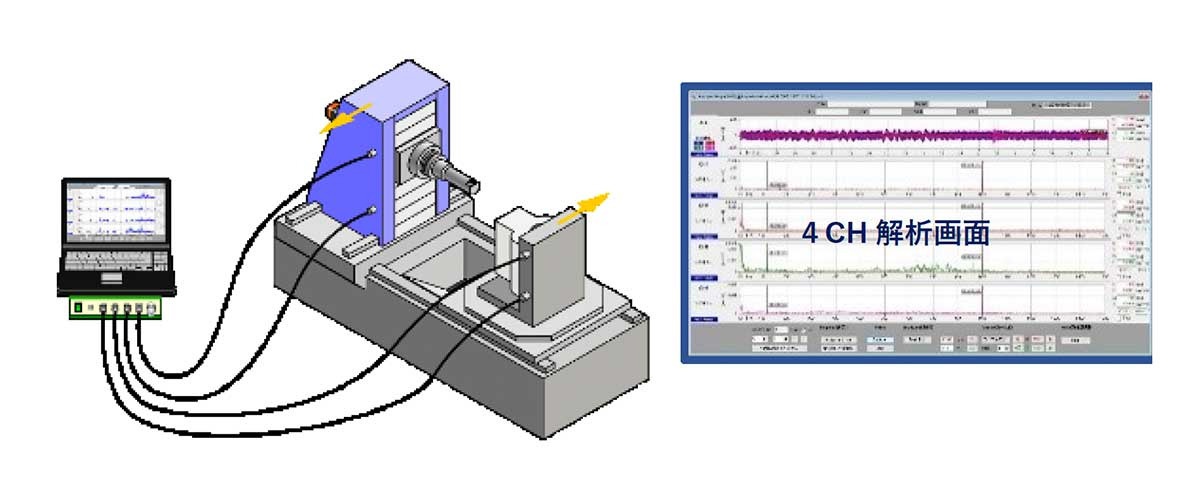

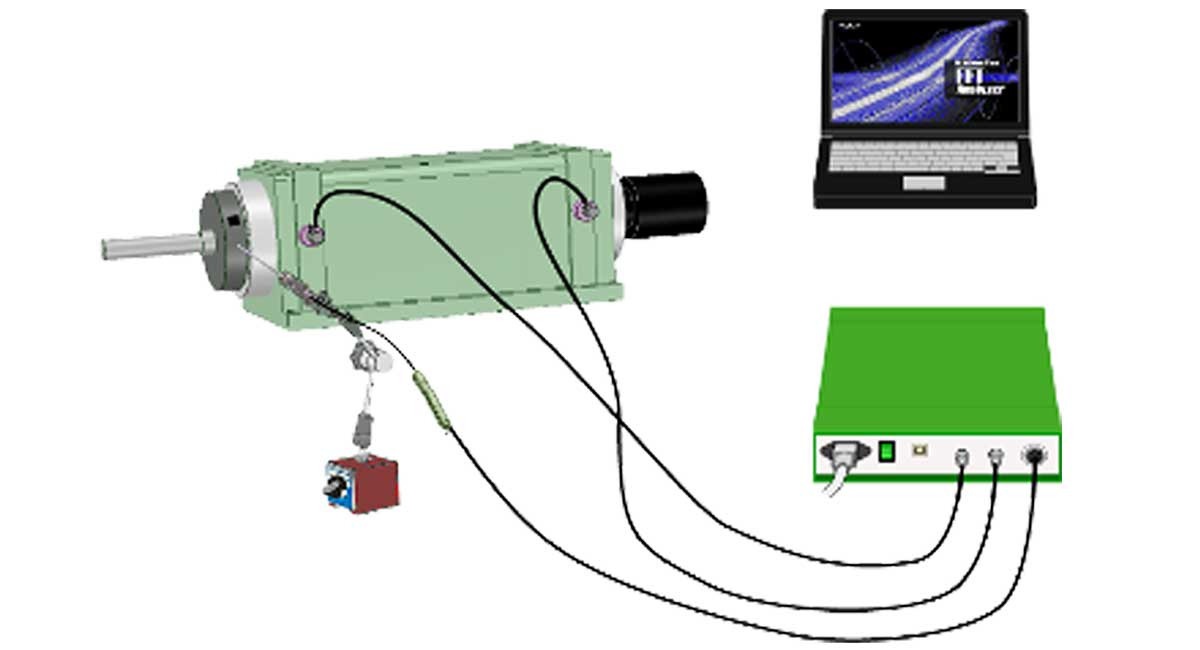

Oscillating vibration measurement

③ Oscillating vibration measurement function

Vibration from processing is transmitted as twisting vibration to machine columns and jigs. The optimum rotation speed is selected for each by observing the relationship between the spindle and jig, and the amplitude and phase of the rotation speed ratio of the spindle in the X and Y directions.

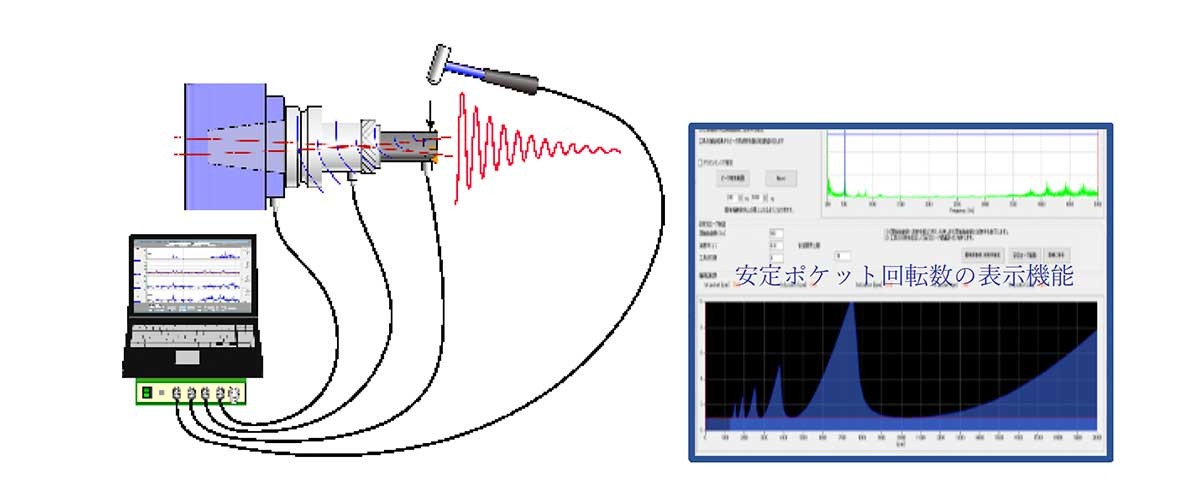

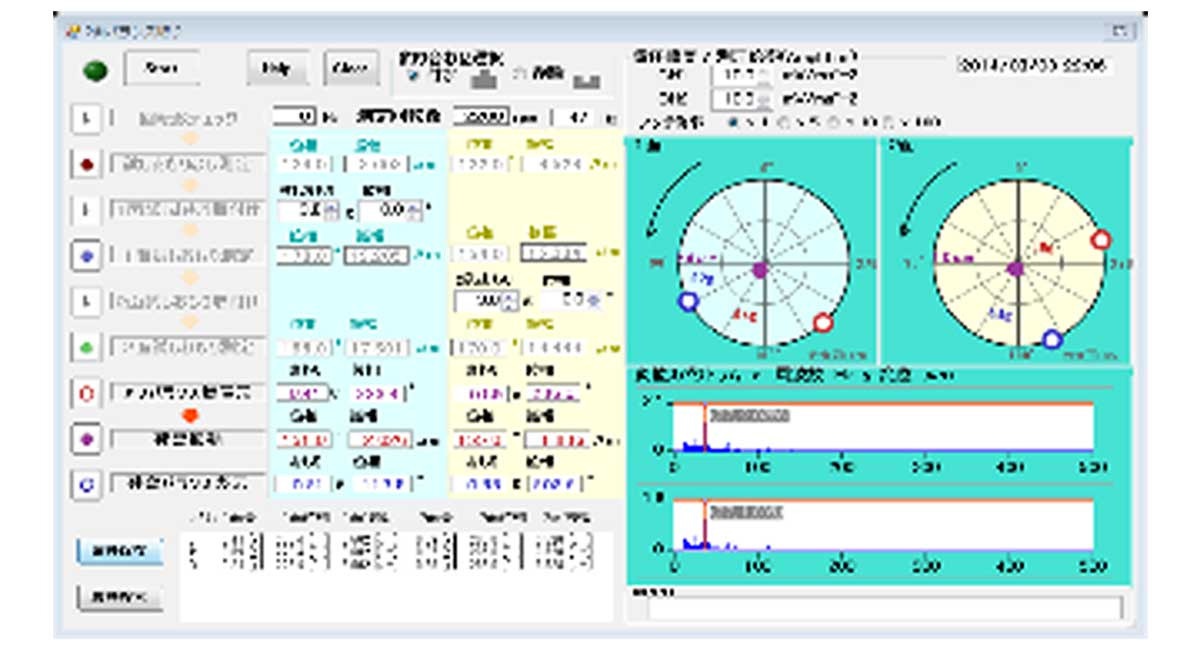

Example of setting acceleration sensor and phase trigger sensor for two-sided balancing

④ Feed balancing function

Check how the balance of the rotating body is.

This function has been added to meet the demand for further balancing and improving the balance accuracy. Easy and intuitive operation according to the guidance display